robodrill

FANUC ROBODRILL is a High Speed, High Precision Compact Machining Centre.

The FANUC ROBODRILL enables fast, accurate machining with the latest in FANUC CNC and Servo technologies. This combination, along with ROBODRILL’s highly reliable and high-speed tool changer will yield impressive parts on time, every time.

Low maintenance and ease of use systems allow the operator to keep track of the necessary required maintenance checks easily.

robodrill KEY FEATURES

- Latest FANUC 31i-B5 Plus control unit with iHMI

- Easy to use 10.4 inch touch screen LCD display

- Quick screens for operation and maintenance

- USB and CF card slots

- AI Contour Control 1

- Manual Guide i

- Custom Macro

- 10,000 RPM Spindle (Optional 24,000 RPM)

- 1.4 second cut to cut tool changer

- 54 m/min rapid traverse speed

- BT30 (Optional BBT30)

- Basic top covers as standard

- Dual Check Safety

- 4MB Part program storage memory

robodrill MODELS

The new generation ROBODRILL vertical machining centre promises unrivalled quality and precision with low running costs. Featuring an unbeatable tool change time of 1.4 seconds and a turret capable of handling tools weighing 3 kg, the standard version Robodrill is both the fastest and strongest compact CNC machine on the market.

α-DSiB5 Plus

Travel (X x Y x Z)

300 x 300 x 330 mm

Working Space (X x Y axis)

630 x 330 mm

Maximum Workpiece Mass

200 kg (Uniform Load)

Tool Capacity

14 or 21 Tool

α-DMiB5 Plus

Travel (X x Y x Z)

500 x 400 x 330 mm

Working Space (X x Y axis)

650 x 400 mm

Maximum Workpiece Mass

300 kg (Uniform Load)

Tool Capacity

14 or 21 Tool

α-DLiB5 Plus

Travel (X x Y x Z)

700 x 400 x 330 mm

Working Space (X x Y axis)

850 x 410 mm

Maximum Workpiece Mass

300 kg (Uniform Load)

Tool Capacity

14 or 21 Tool

ADVANCED VERSION ROBODRILL

Designed for cutting edge high-speed machining and to set the performance benchmark in their class.

Advanced Version Robodrills provide the ultimate in precision and repeatability, they are perfect for long fully automated production runs and represent a versatile alternative to larger machines.

Features

Ultra Fast Servo Turret

0.7 second tool change time

400 mm Z axis travel

Up to 4 kg per tool capacity

Z axis metal cover

Power failure backup module

robodrill ACCESSORIES

ROBODRILL DDRiB is a high speed, highly accurate 4th axis that is available exclusively for the FANUC ROBODRILL. This 4th axis features a direct drive built in servo motor that enables extremely fast and accurate indexing. The DDRiB is an extremely compact unit that occupies very little space on the ROBODRILL table.

DIRECT DRIVE 4th AXIS

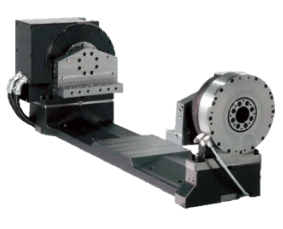

ROBODRILL DDR-TiB features a DDR-TiB 4th axis with tail support. The tail support boasts a clamping mechanism which works together with the DDR-TiB to enable rigid machining between the two support points. The shape of the DDR-TiB also utilizes as much space as possible to allow even bigger parts to be machined.

DIRECT DRIVE 4th AXIS WITH FOLLOWER