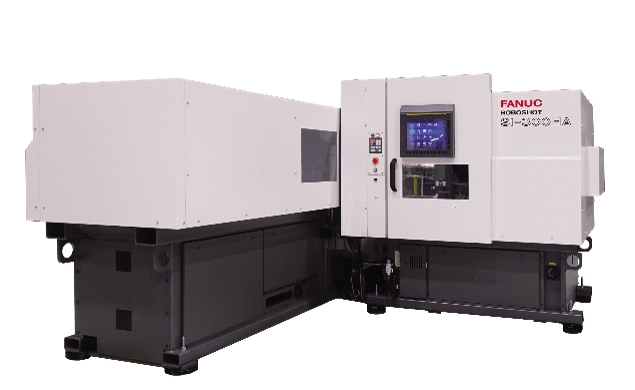

FANUC ROBOSHOT is a Highly Reliable, High Performance and High Precision Plastic Injection Molding Machine.

Conforming to global safety standards and offering superior Robot system interoperability. The FANUC ROBOSHOT achieves superior molding repeatability with full electric FANUC Servo systems and the latest in FANUC CNC technology.

Low maintenance and ease of use systems allow the machine to run unmanned for long time periods while keeping running costs to a minimum.

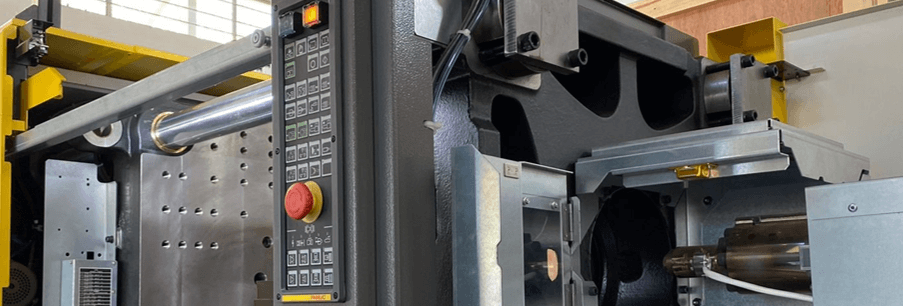

roboshot KEY FEATURES

- Latest FANUC 31i-B control unit with iHMI

- AI mold protection

- Input lock function

- AI metering control

- Power consumption monitor

- Auto purge

- USB interface

- Injection pressure alarm

- EU67 picker interface

- Container management

- Bad parts reject function

- Low temperature holding

- CE certified safety

- AI ejector system

roboshot MODELS

ROBOSHOT RANGE

α-S15iB

| Tonnage (kN): | 150 |

| Optional Increased Tonnage (kN): | – |

| Tie Bar Spacing (H x V mm): | 260 x 235 |

| Screw Diameter (mm): | 14-18 |

|

Injection Stroke (mm): |

50 |

|

Injection Volume (cm3): |

9-19 |

|

Injection Speed (mm/s): |

800 |

α-S30iB

| Tonnage (kN): | 300 |

| Optional Increased Tonnage (kN): | – |

| Tie Bar Spacing (H x V mm): | 310 x 290 |

| Screw Diameter (mm): | 14-22 |

|

Injection Stroke (mm): |

60 |

|

Injection Volume (cm3): |

9-29 |

|

Injection Speed (mm/s): |

600 |

α-S50iB

| Tonnage (kN): | 500 |

| Tie Bar Spacing (H x V mm): | 360 x 320 |

| Screw Diameter (mm): | 18-32 |

| Injection Stroke (mm): | 70 |

| Injection Volume (cm3): | 19-76 |

| Injection Speed (mm/s): | 350-550 |

α-S100iB

| Tonnage (kN): | 1000 |

| Tie Bar Spacing (H x V mm): | 460 x 410 |

| Screw Diameter (mm): | 22-40 |

| Injection Stroke (mm): | 100 |

| Injection Volume (cm3): | 29-181 |

| Injection Speed (mm/s): | 200-650 |

α-S130iB

| Tonnage (kN): | 1300 |

| Tie Bar Spacing (H x V mm): | 530 x 530 |

| Screw Diameter (mm): | 29-40 |

| Injection Stroke (mm): | 100 |

| Injection Volume (cm3): | 50-181 |

| Injection Speed (mm/s): | 200-650 |

α-S150iB

| Tonnage (kN): | 1500 |

| Tie Bar Spacing (H x V mm): | 560 x 510 |

| Screw Diameter (mm): | 22-52 |

| Injection Stroke (mm): | 150 |

| Injection Volume (cm3): | 29-442 |

| Injection Speed (mm/s): | 200-650 |

α-S220iB

| Tonnage (kN): | 2200 |

| Tie Bar Spacing (H x V mm): | 650 x 650 |

| Screw Diameter (mm): | 32-56 |

| Injection Stroke (mm): | 150 |

| Injection Volume (cm3): | 121-512 |

| Injection Speed (mm/s): | 200-350 |

α-S250iB

| Tonnage (kN): | 2500 |

| Tie Bar Spacing (H x V mm): | 710×635 |

| Screw Diameter (mm): | 32-56 |

| Injection Stroke (mm): | 200 |

| Injection Volume (cm3): | 121-640 |

| Injection Speed (mm/s): | 350 |

α-S300iB

| Tonnage (kN): | 3000 |

| Tie Bar Spacing (H x V mm): | 810×710 |

| Screw Diameter (mm): | 40-80 |

| Injection Stroke (mm): | 200 |

| Injection Volume (cm3): | 188-1608 |

| Injection Speed (mm/s): | 160-350 |

α-S450iB

| Tonnage (kN): | 4500 |

| Tie Bar Spacing (H x V mm): | 920×920 |

| Screw Diameter (mm): | 40-100 |

| Injection Stroke (mm): | 250 |

| Injection Volume (cm3): | 188-2827 |

| Injection Speed (mm/s): | 180-350 |

roboshot ACCESSORIES

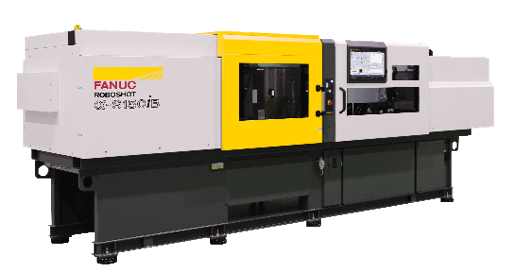

SI-20A

ROBOSHOT SI-20A is a vertical second injection unit that can be added onto the ROBOSHOT. It offers the same FANUC precision and repeatability in a compact package. Available with multiple screw diameters and a maximum injection speed of 300 mm/s

SI-300HA

ROBOSHOT SI-300HA is a horizontal second injection unit that can be added to the ROBOSHOT. It offers the same FANUC precision and repeatability with a built-in control unit. Available with multiple screw diameters and a maximum injections speed of 330 mm/s.